Ipeni-uhlobo lweqokelelo yeNqaku leNkampani

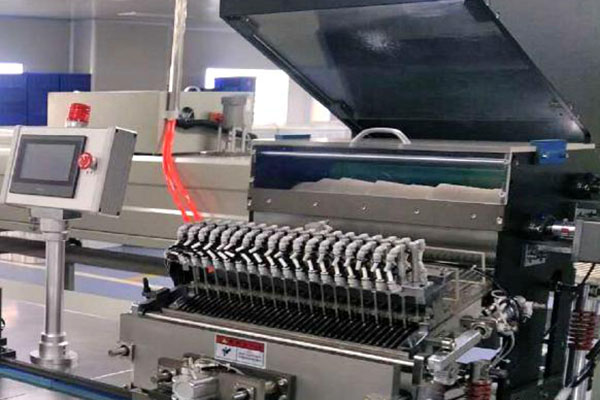

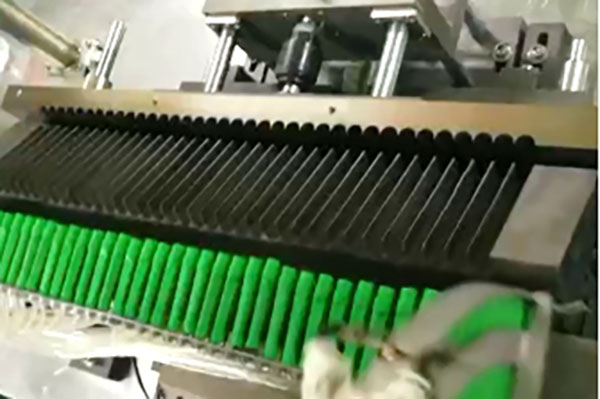

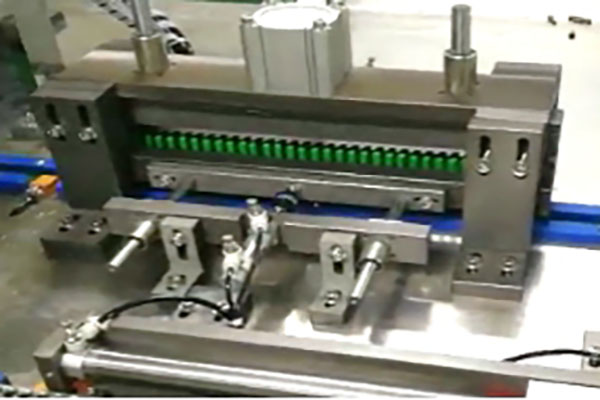

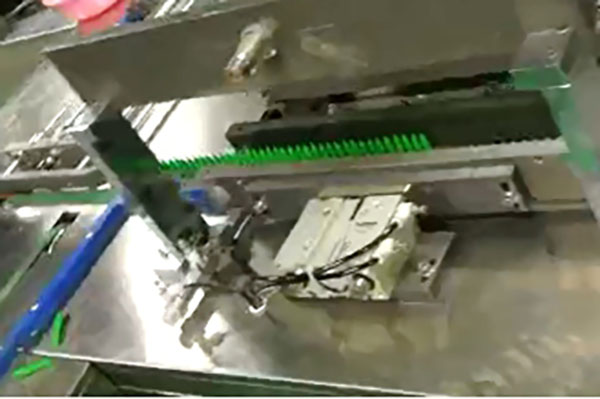

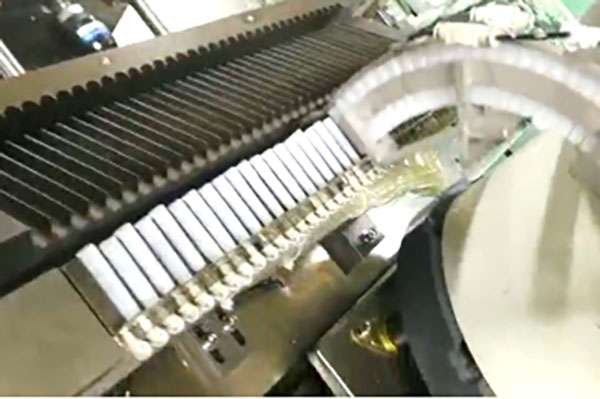

Ipenitshala ye-peni-ten ye-pening yegazi ibonelela ngomgangatho ophezulu, uhlangabezana nemigangatho yeshishini, kwaye iguquguquka kwi-21g, i-22g kunye nolunye ubukhulu. Uyilo oluguqukayo, lunokuhlengahlengiswa ngokweemfuno ezizodwa, iindlela ezahlukeneyo zokusebenza zinokukhethwa, kubathengi ukuba basebenze indleko kunye nokuphucula ukusebenza ngempumelelo. Umthamo wokuvelisa unokufikelela kwi-12000-15000ccs / iyure.

Izixhobo zamkela i-Preeve ezininzi zokucinezela kunye neyunifomu yokungalingani ngokukhawuleza yokuphucula umgangatho wemveliso. Imisebenzi efana nokuchongwa kwe-fiber offic, indawo ezenzekelayo kunye ne-CCD ekuboneni komgangatho wokuqinisekisa umgangatho wemveliso ngexesha lemveliso kunye nokuphucula ukusebenza ngempumelelo ngexesha elinye.

Inaliti yokulayisha inaliti

| Inaliti esebenzayo | Uhlobo lwepeni |

| Isantya sokusebenza | I-12000-15000PCcs / iyure |

| Ukuchongwa kwe-CCD nge-nenank glitch | I-0.05 * i-0.05 (esekwe kwi-TIP yokunyamezela i-0.3) |

| Amandla | I-380v / 50 okanye 60hz, 16kw |

| Umoya oxinzelelweyo | Uxinzelelo loMoya ocociweyo lwe-0.6-0.8MPA |

| Abasebenzi abaSebenzayo | I-5-6 |

| Umsebenzi wendawo | I-6080 * i-11200 * i-1800 mm (l * h * h) |

| Ubunzima | I-9000kg |

| *** Qaphela: njengoko iimveliso zihlala zihlaziywa, nceda uqhagamshelane nathi ngenkcazo yamva nje. *** | |