I-Peritoneal Dialysis Solution (CAPD) Umgca wokuvelisa

YethuI-Peritoneal Dialysis Umgca wokuvelisa isisombululo, kunye nesakhiwo esiQinisekileyo, esithatha indawo encinci. Kwaye data ezahlukeneyo zinokuhlengahlengiswa kwaye zigcinelwe ukuwelda, ukuprinta, ukuzaliswa, i-CIP kunye ne-SIP njengobushushu, ixesha, uxinzelelo, nako kunokuprintwa njengoko kufuneka. I-drive ephambili idibaniswe yi-servo motor enebhanti ye-synchronous, indawo echanekileyo. Imitha yokuhamba kobunzima obuphezulu inika ukuzaliswa ngokuchanekileyo, umthamo unokulungelelaniswa ngokulula ngonxibelelwano lomntu.

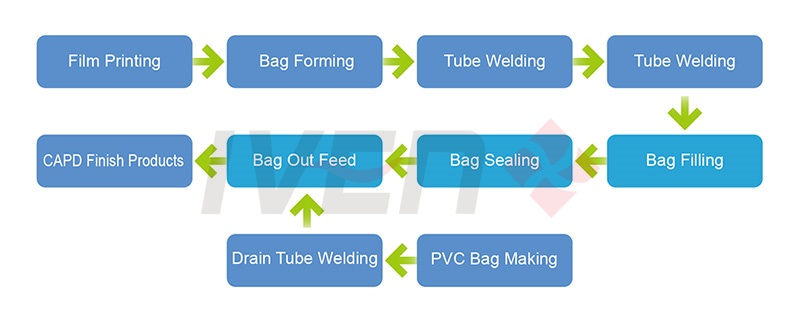

Ukuprintwa kwengxowa yesisombululo seCAPD, ukubumba, ukuzalisa kunye nokutywinwa, i-tube welding, i-PVC yokwenza isikhwama somatshini.

welding Peripheral kunye nesakhiwo sokubumba evulekile kabini kunye nokuguquguquka ngundo ixhotyiswe ipleyiti yokupholisa, ukwenza ukuguquguquka ngundo ubushushu efanayo, kwaye uqinisekise ukuba izixhobo kwinkqubo yokubumba kunye nokuyeka aziyi kubhaka izinto inwebu eshushu; Kuphuculwe umgangatho wemveliso.

Umbhobho wokufudumeza kunye ne-thermocouple kwi-aluminium i-alloy yokufudumeza ipleyiti, ukufudumeza kunye nokudluliselwa kobushushu kuyafana, ulawulo lobushushu luchanekile, lunciphise ilahleko yobushushu, aluyi kubonakala ubushushu bokwenyani kunye nobushushu bokubonisa aluhambelani, ukuze kuqinisekiswe izinga lokufaneleka kwe-welding.

I-100% yokusetyenziswa kwefilimu, akukho mda wenkunkuma phakathi kweengxowa kunye namaqela.

Ukubumba ukubumba kuyilwe ngokukodwa. Isingxobo sokugqibela esenziweyo seqela langaphambili siya kusikwa kunye nengxowa yokuqala eyenziweyo yeqela lamva. Kukulungele ukutsalwa kwefilimu xa usolula iingxowa. Inkqubo enye kuphela inokuqinisekisa ukolula kwefilimu kunye nokwelula kwebhegi kunokwenziwa ngokuhambelanayo. (ukuqinisekisa ubude befilimu obufanayo bexesha ngalinye phakathi kweqela ngalinye, oko kukuthi, akukho siphelo senkunkuma phakathi kwamaqela ahlukeneyo - umenzi wasekhaya ukhona umda wenkunkuma phakathi kweqela ngalinye.)

Xa utshintsha ukungunda kwiinkcukacha ezahlukeneyo zeemveliso, kufuneka utshintshe kuphela ukungunda okuphezulu, ukungunda okusezantsi kuhlengahlengiswa ukungunda ngokubanzi, okunokusindisa kakhulu ixesha lokulungisa umonakalo. Ukwenza isikhunta senziwe ngezinto ezikhethekileyo kunye nenkqubo ekhethekileyo yabenzi bokubumba abakhethekileyo, abaqinisekiswanga ukuba bangaphawuli umgangatho kunye nobomi benkonzo yeengxowa ze-100 yezigidi.

Ngokweempawu zokuwelda iplastiki, i-welding ebandayo kufuneka yamkelwe ngoko nangoko ukuze yenziwe emva kokuwelda ezimbini zobushushu obuphezulu. Oku kunokuqinisekisa ukuqina kwe-welding yeplastiki kunye nokuzisa inkangeleko entle. Ke ngoko, izibuko zokuwelda ze-2 zidinga ukuwelda okubandayo, kunye nobushushu be-welding yobushushu bamanzi okupholisa okwenyani (15ºC-25ºC), ixesha kunye noxinzelelo luyahlengahlengiswa.

Ngoyilo lwelungelo elilodwa lomenzi wechiza, isitishi sokususa inkunkuma silula kwaye sithembekile, izinga lokuphumelela eliphezulu ukuya kuthi ga kwi-99% nangaphezulu. Izibonda ezingaphezulu nezisezantsi zibambe ifilimu yenkunkuma emva kokuba ibhegi yenziwe kwaye iyikrazule ngecylinder yesikhokelo, ukugqiba ukwenza ingxowa. Umda wenkunkuma engunxantathu uqokelelwa ngesixhobo esikhethekileyo. Isikhululo sokususa inkunkuma esizenzekelayo asikwazi ukunciphisa kuphela imiphumo emibi yokukrazula okwenziweyo, kodwa nokuqinisekisa ukumila kwesikhwama esihle.

Yamkela i-E + H mass flowmeter measurement kunye nenkqubo yokuzalisa uxinzelelo oluphezulu.

Ipompo yokulawula i-frequency ilawula uxinzelelo, sebenzisa umbhobho we-silicone yonyango ochasene noxinzelelo oluphezulu ukudibanisa umbhobho, ukugcinwa lula, akukho ndawo yokucoca efile.

Ukuchaneka kokuzaliswa okuphezulu, akukho sikhwama kwaye akukho sikhwama esifanelekileyo, akukho ukuzaliswa.

Iintloko zokuzalisa zamkela iteknoloji ye-patent yokutywinwa kwendawo egudileyo, akukho qhagamshelwano kunye namachweba e-interwall ngoko kungabikho ukungqubuzana ukuvelisa amasuntswana; iphinda ithintele ukuphuphuma kwesisombululo esibangelwa utshintsho lobungakanani bezibuko ukwenza izibuko zingavalwanga ngeentloko zokuzalisa.

Yamkela ulawulo lwe-PLC oluphambili kunye nendlela edibeneyo ye-valve terminal, isiphaluka esilula, ukuphendula ngokukhawuleza kokusebenza, ukugijima okukhuselekileyo nokuthembekileyo. Ukuzalisa inxalenye idityaniswe kunye nenxalenye yokutywinwa kwiyunithi enye, idinga kuphela inkqubo yokulawula umbane kunye neyunithi enye yokusebenza komatshini wokudibanisa; ubuncinane omnye umqhubi uyancitshiswa, aphephe izinto ezingalunganga njengokungahambelani phakathi kwabaqhubi ababini, kwaye kwandisa ukhuseleko kunye nokuthembeka kwezixhobo.

Isibonisi sesikrini sokuchukumisa kwaye sisebenza lonke ulawulo lobushushu ngokuchanekileyo. Ngokukodwa inika ukuguquguquka okuncinci ekuqaleni kunye nokuyeka, ukunyamezela kunokuba ±1℃.

Iphaneli yokushicilela ifakwe kwipleyiti ye-aluminiyam nge-S / S stud bolt, uthintele intambo yomngxuma ekhululekile kwipleyiti emva kokusetyenziswa kwexesha elide.

Umqulu wefilimu ubekwe ngoxinzelelo olufanayo ukusuka kumacala angama-4 ukuqinisekisa ukunyanzeliswa kwefilimu kunye nokusebenza kakuhle. Umqulu wefilimu ngasekhohlo kunye namacala asekunene agxininiswe yi-plate yokubeka i-adjustable, ukuqinisekisa isantya sokutya kunye nokuchaneka.

Isikhululo sokufudumeza kunye nesikhululo sokutywinwa kobushushu samkele i-spring-loaded probe yenaliti ukubona ubushushu bokubumba, ukufakwa ngokulula kunye nokuqhaqha, akulula ukwaphuka, ukunyamezelana ngaphakathi kwe-± 0.5℃.

Guqula indlela yokutywinwa kokubeka ukukhusela i-cylinder, ugweme ukufudumeza ixesha elide kuyo.

Iingcingo zobuchwephesha zangaphandle, zahlula ucingo ngokulandela ukuhlelwa okwahlukileyo, inkangeleko entle kunye nolondolozo olufanelekileyo.

Lungisa isikhunta esisezantsi, kodwa gcina ipleyiti yokupholisa, ukukhusela ifilimu xa umatshini uvala.

Ukutywinwa kobushushu obujikelezayo kwamkela ukungunda okukhethekileyo, faka ipleyiti yokupholisa yesikhunta esiphezulu kunye nentwasahlobo-elayishiwe.

Yongeza inkqubo yokutya ngokuzenzekelayo ukusombulula ingxaki yokuthintela kunye ne-jamming, ukunciphisa ukuqina kwabasebenzi. Yongeza i-ionic yokucoca umoya kunye nesixhobo sokubuyisela ukuphucula ukucaca kwemveliso.