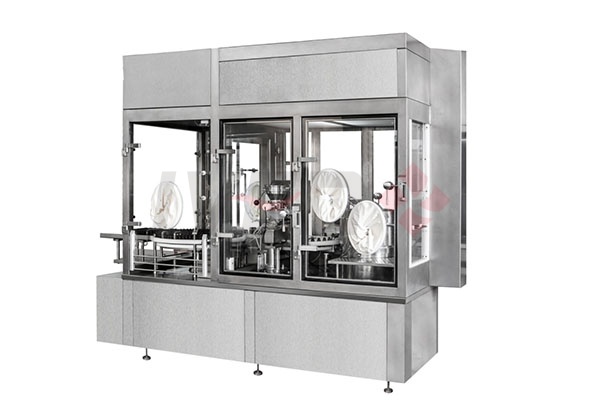

I-Vial Liquid Filling Production Line

Kwimveliso yeglasi yeglasi

| Umzekelo | Umgca wokuvelisa | Ubungakanani obufanelekileyo | Imveliso(ubuninzi) | Amandla | Ukusinda okushiyekile | Ubungakanani bubonke |

| BXKZ I | I-CLQ 40 | 2.25ml | 6000-12000 iipcs/h | 69.8KW | 7500Kg | 9930×2500×2340mm |

| RSM 620/44 | ||||||

| KGF 8 | ||||||

| BXKZII | I-CLQ 60 | 2.25ml | 8000-18000 iipcs/h | 85.8KW | 8000Kg | 10830×2500×2340mm |

| RSM 620/60 | ||||||

| KGF10 | ||||||

| BXKZ III | I-CLQ 80 | 2.25ml | 10000-24000 iipcs/h | 123.8KW | 8100Kg | 10830×2500×2340mm |

| RSM 900/100 | ||||||

| KGF 12 |

*** Qaphela: Njengoko iimveliso zihlaziywa rhoqo, nceda uqhagamshelane nathi ngeenkcukacha zamva nje. ***

Thumela umyalezo wakho kuthi:

Bhala umyalezo wakho apha kwaye uwuthumele kuthi